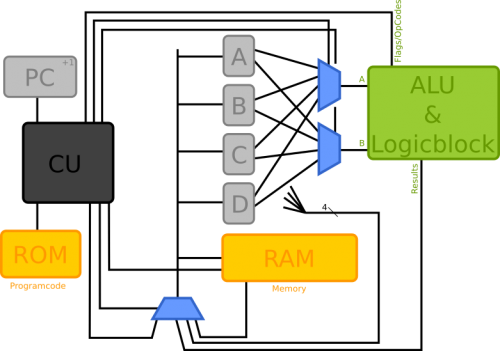

EuroTwo CPU

Status

Follow #eurotwo on twitter. :)

2021-05-06

Seems that the connection solution is not optimal. The Cu zone is to close to the mounting hole. So the cable scratches the solder mask and creates short circuits. My current solution is to use plastic washers to create some distance. But now the nuts on the bottom of the boards are required to directly touch the boards for a reliable connection. Microscope images of the follow.

2021-04-15

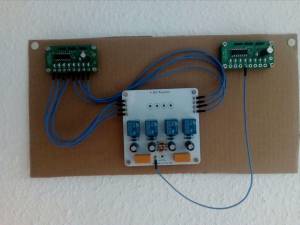

Mounted the first boards on the backplane. I started again with the ALU, similar to the preproject. Some wires left. Also the zero-detection logic is not mounted yet. But so far everything seems to work perfectly!

2021-01-30

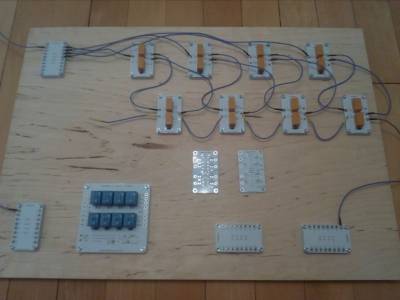

Printed and assembled 12 nut- and distance holders for the distributors. Also in the meantime the new (buffer/inverter/levelshifter) board arrived. The controlled buffer functionality has a small, and fixable bug. Lessons Learned: For the next time consider 2.54 TH jumpers instead of solder bridges, just for flexibility.

2021-01-23

2021-01-10

New stuff arrived. Making cables. Designing new cases for the Digital Controllers, more stuff…

2021-01-03 (later)

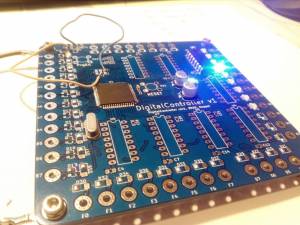

Assembled the second DigitalController and wrote code for RAM simulation. It seems to work fine! Found that some more input pins would be of more value then output pins. But that is hackable. https://twitter.com/nopx15/status/1346104293137539073

2021-01-03

After I found that the ISP programming pins are wrong, I successfully programmed the first digital controller. The clock simulation is now up and running. Next RAM and ROM simulation. That will be a software task. It is fun to work digital again!

2021-01-02

I made a bunch of power cables today. Also I ordered a lot of screws and other stuff. Hopefully tomorrow my board will arrive!

2020-12-31

I soldered 5 more MUXs. Also I ordered ~100 new PCBs. Distributors, HalfAdders, LogicBlocks like Inverters and stuff, and also a Digital Controller to simulate ROM, RAM, and the ControlUnit. The plan is to replace the DigitalControllers bit by bit. Starting with the control unit. Assumed I own enough cables, clips, relays and screws I should own everything to have a running CPU in the next few days.

2020-10-28

I tried a different setup of the logo illumination by using two PCBs. I sanded the backside of the first PCB and assembled the LED in the other direction on the second one. This look much smoother and better!

2020-10-18

2020-08-10

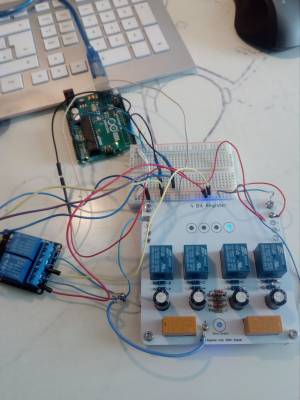

I designed a testing board with a SN754410 H-Bridge driver for testing. I can test 4 outputs and 4 inputs per testing board easily with an Arduino now. The SN754410 is still in delivery and will get assembled later. Tweet, including a short video of the testing

2020-08-01

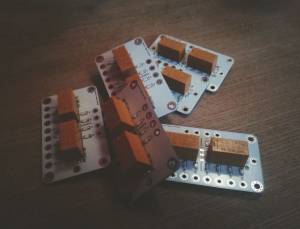

My automated long term test is up and running. 1000 test-iterations per bit. Tuned the loading speed of the C (adding 100 Ohms), added diodes (1N4007) and tuned the holding voltage of the relais better by adding 100 Ohms.

2020-06-28

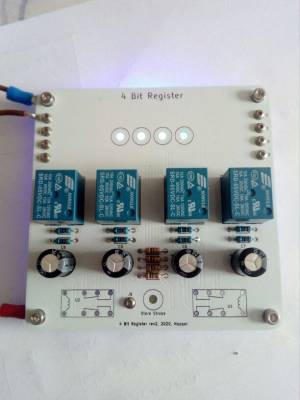

Fixed the „4-Bit Register rev2“ board. The board is fully functional but has some drawbacks. You need to scratch away 8 traces on the board and solder 8 short wires on it.

The fixes for rev3 are:

- Cs were not aligned correctly to matching relais. Nobody will see this but still, it is not as intended! Fixed in rev3

- There is a mistake at the store relays. That is why you need to scratch traces. Fixed in rev3

- Rev2 is unable to select between rising and falling edge. This is fixed in rev3 by a jumper

- B.Mask is under the LED-Indicator on the back, that is why the light is not as bright as intended. Fixed in rev3.

- Numbering of the LEDs would be helpful. Fixed in rev3.

2020-06-18

The PCBs for the 4Bit Register and the Logo did arrive. I assembled them successfully. I'm now waiting for the new Relays HK19F for the final test of the registers. In the Logo-PCB there was a little mistake but I succeed fixing it by scraping away two traces.

Documentation

Downloads

- EuroTwo OnePiece v0.004.0 Schematic [PDF] (untested)

Sizes/Standards

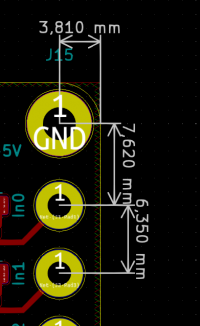

- Holes for signals: 2_2mm vias or pads

- Holes for currents: 3.2

- GND on top holes

- +5V on bottom holes

- Small boards: 39,370mm x 67,310mm

- Big boards: 99,060mm x 99,060mm

Errata

ALL

- Clearing around M2 holes bigger! The problem is that after some mountings and unmountings the soldermask gets holes and the Cu gets through. You got a short circuit than. Not good! Workaround: DIN125-ISO7089-Kunststoff-Polyamid-PVC-Beilagescheiben-M2

HalfAdder rev1

- Silkscreen: AxorB → A&B

DigitalController rev1

- RX0 and TX0 instead of MOSI and MISO for ISP (see https://www.mikrocontroller.net/topic/477873)

- R1: 0603 → 0804

- Silkscreen: Reset ↔ PrgEn

- PrgEn button not needed!

- Silkscreen: R55 not readable

Inverter / Level / Buffer rev1

- Silkscreen: LOW_A and LOW_B switched

- En_A und En_B and High!